CRI – about us

Who we are

CRI Group is a capital group comprising enterprises with a service-oriented business profile. The group’s companies are specialized entities operating in the area of process outsourcing, in the fields of quality control, production, logistics, after-sales support, and employment agency services.

Since the beginning of our operations dating back to 2003, we have focused our activities on services dedicated to industrial production and the automotive sector, which remains the leading industry we work with to this day. Currently, we also cooperate with international corporations in the home appliances, consumer electronics, and logistics industries.

With years of experience and a high degree of versatility in our service applications, we are able to effectively and efficiently transfer solutions to almost any industrial sector.

The group’s priority is to take on new challenges that allow us to maintain a stable pace of development. We take pride in the fact that no problem is unsolvable for us, always acting with the intention of supporting our clients in every possible area. Thanks to this approach, we design, launch, and develop new projects, which are often innovative and tailored solutions for our clients.

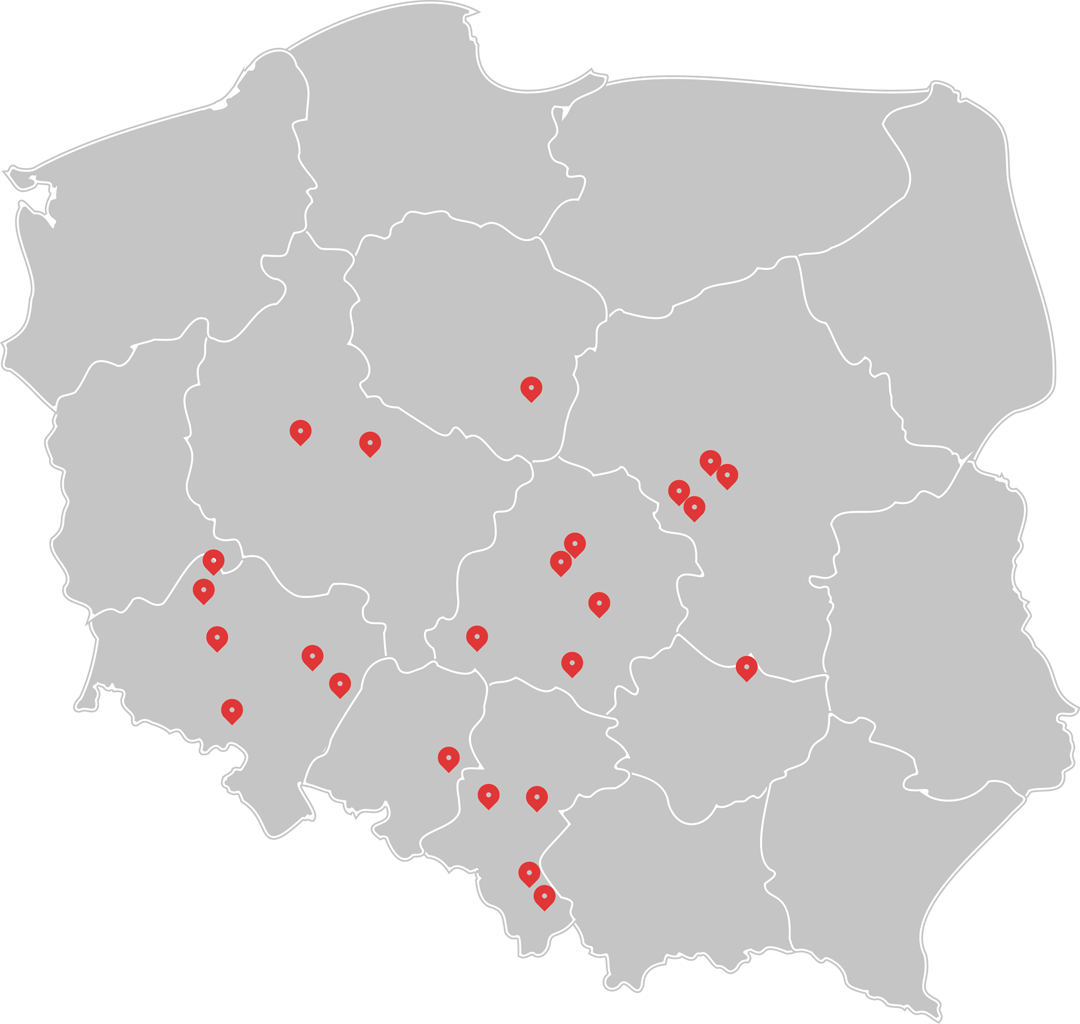

Our nationwide service coverage in more than 20 locations in Poland translates into high operational flexibility and quick response to our clients’ needs, making us a leader in process outsourcing dedicated to mass production industrial plants.

Mission and Vision

Mission

Our mission is to provide the highest quality services. We achieve this by instilling a sense of responsibility for work quality among our employees and engaging them in continuous improvement of process performance. The Kaizen philosophy is an integral part of our daily operations and a key pillar of continuous improvement within the Lean Manufacturing framework.

Vision

We aim to create a recognizable and professional brand image, which, through high effectiveness and reliability of provided services, will have a significant impact on the success of our clients.

Business locations

- Grójec

- Pruszków

- Żyrardów

- Mszczonów

- Ożarów Mazowiecki

- Łódź

- Radomsko

- Piotrków Trybunalski

- Wieluń

- Pabianice

- Starachowice

- Włocławek

- Żywiec

- Bielsko-Biała

- Sosnowiec

- Gliwice

- Strzelce Opolskie

- Polkowice

- Głogów

- Poznań

- Września

- Wrocław

- Oława

- Legnica

- Wałbrzych

We operate nationwide, with presence in over 20 locations across Poland.

We consistently expand our operations, which directly increases our flexibility and speed of response to our clients’ needs.

Since the company was founded, we have paid special attention to standardizing internal processes in order to continuously improve the quality, effectiveness and reliability of the services provided. After only one year of operation in 2004, we implemented the ISO 9001 Quality Management System, which was confirmed by the issuance of a certificate by TUV Rheinland. The ISO 9001 system has been operating effectively in the capital group to this day, and we currently also work in accordance with the requirements of the ISO 14001 environmental standard and VDA 6.1, VDA 6.3 standards.

Our operational strategy is defined, among other things, by the Quality Policy, which is presented below in its current form.

Our most important quality criterion is customer satisfaction.

The aim of the activity is the constant development and strengthening of the company’s position on the market. The success of the company can be ensured by the constant satisfaction of the Customers. An important component of this aim is the fulfillment of the requirements of the Customers, reliability and high quality of the services provided.

We achieve our goals by:

- active participation of the company’s management in the implementation of the quality policy,

- continuous supervision and improvement of process functioning,

- periodic customer satisfaction and expectations surveys,

- optimization of management processes and information flow,

- raising employee competences and improving relationships between them,

- shaping the sensitivity of employees to quality with all the means at our disposal,

- building a sense of responsibility among employees for the quality of their work,

- involvement of all employees in improving the quality of services provided and improving the Quality System.

The implementation of the Quality Policy is ensured by compliance of work with the Quality Management System, which meets the requirements of the ISO 9001:2015 standard and the Management Board’s commitment to respect all arrangements in this respect.

Benefits of cooperation

Companies are constantly seeking methods and solutions that will optimally reduce costs and allow them to focus on their core business. To meet these needs, we have developed a range of dedicated outsourcing services designed to comprehensively support various processes within a manufacturing enterprise.

The implementation of our solutions brings a number of benefits, the most important of which include:

- cost reduction and control,

- increased flexibility and efficiency in project execution,

- enhanced safety of project implementation,

- quality improvement,

- freeing up internal resources for other purposes,

- access to resources the company does not possess,

- handling functions that are difficult or impossible to perform or control,

- process improvement.

For example:

Cost reduction and control

- downtime,

- absenteeism,

- vacation benefits,

- recruitment,

- initial and periodic medical examinations,

- occupational health and safety and fire protection training,

- workwear and personal protective equipment,

- on-the-job training,

- work organization and coordination,

- notice periods,

- HR and payroll services,

- low work quality and productivity.

Additionally, in cooperation models that involve collaboration with the client’s suppliers, we apply discount systems that significantly reduce the base hourly or piecework rates previously agreed with the client.

All tasks we carry out are subject to detailed reporting. Our reports include, among others:

- working time,

- actual work efficiency,

- total service cost,

- PPM and Pareto analysis,

- process results – completed operations,

- observations, suggestions, etc.

We report on a daily, weekly, monthly basis, or individually upon the client’s request. Our reports are not only a tool for effective cost control but also a rich source of ready-to-use data that helps identify problems and risks. They serve as input for corrective and preventive actions.

Increased flexibility and efficiency of process execution

For most services, we guarantee a 60-minute response time to the client’s demand, and in all cases full 24/7 availability. We flexibly provide personnel that the client does not have, tailored to the demand. This is staff with the predispositions and skills required to perform specific tasks, coordinated by a team of qualified managers. Our approach to tasks is goal-oriented, based on the objectives defined by the client. This means we take full responsibility for the final result, and any failure lies solely with us. That’s why it is so important to continually increase the efficiency and effectiveness of the services we provide, as it is not only in the interest of our clients but especially in our own.

Clients

We are proud of the companies we work with.

Below we present a selection of some

of the many Clients we serve.

Powyższe logotypy nie stanowią własności CRI Poland sp. z o.o. i służą wyłącznie do celów informacyjnych.

References

Customer satisfaction is our priority, which is why we regularly assess the level of satisfaction with our cooperation. The knowledge we gain allows us to better understand the requirements and needs of our clients and continuously improve the quality of the services we provide.

We present a selection of the many recommendations we have received. Original documents are available for review upon request from interested parties.

I am providing a reference for CRI, which carried out services for the Logistics Department at the Brose-Sitech sp. z o.o. facility in Polkowice from 09.2021 to 07.2024. The services involved in-plant transport of finished products, car seat structures, and components between the logistics center and the production halls. The service was performed using entrusted transport equipment, primarily tow tractors and transport platforms.

With this letter, I confirm the reliability and timeliness of the service provided and recommend CRI as a professional and responsible service provider in the aforementioned area.

CRI carried out sorting tasks for Autoliv involving defective parts delivered by a supplier, effectively resolving a quality issue on our production line. The overall rating of the services provided is “very good,” which proves CRI’s professional preparedness for performing quality control services. CRI operates in accordance with the ISO 9001 standard, which makes it a highly recommended partner in addressing quality-related issues.

I express my appreciation for CRI, headquartered in Grójec, which demonstrated professionalism in performing inspection and repair tasks for components delivered to our facility. CRI’s employees showed due diligence and high competence in resolving quality issues. Based on the above, I recommend CRI as a reliable and trustworthy partner.

CRI provided our facility in Pruszków with services in the area of quality control and repair of components as well as final products. The results met our requirements. The reliability and professional approach of CRI’s employees are just some of their many strengths. No non-conformities were found during the inspection of completed work. Our cooperation to date gives us reason to believe that CRI will handle similar tasks just as effectively.

I can fully and confidently recommend the services of CRI. Our cooperation with CRI proved to be extremely helpful and entirely satisfactory. The work was carried out efficiently and with appropriate attention to detail. Excellent communication allowed all our additional requirements to be taken into account. CRI is a trustworthy company, which I strongly recommend as a professional service provider.

Company CRI has been performing 100% quality control of final products in prototype, pre-series, and series production phases for BMW, Mercedes, Suzuki, and Fiat projects on behalf of Hutchinson since 2014.

Throughout the cooperation, CRI has demonstrated a consistently high level of service, flexibility, and timely order execution. The company also responds promptly when needed in other areas, such as component quality control within the incoming inspection department.

Particular recognition is due for CRI’s high level of involvement, its ability to quickly adapt to different workplaces and conditions, and for delivering control reports on time, including detailed graphical analysis.

I recommend CRI as a trustworthy and reliable service provider.

Since February 2016, CRI has been providing our company with quality control services, as well as component repair and sorting.

CRI performs the entrusted tasks in a timely and reliable manner, demonstrating professionalism in its operations. Our cooperation has been characterized by mutual understanding and prompt resolution of emerging issues.

In our opinion, CRI is a company worth recommending, especially for its expertise and competence in the services it provides.

Since 2015, CRI has been providing our facility with outsourcing services, which include, among others:

- incoming inspection of components and outgoing inspection of finished products in terms of visual and functional criteria, based on sampling and in accordance with TCL quality guidelines,

- repair of finished products involving a range of operations to restore the expected features and parameters of the product, e.g., updating firmware on mainboards, replacing defective components or equipment,

- precision operations such as soldering components onto mainboards,

- accessory assembly,

- warehouse-related activities such as order picking and preparing the required product configuration for dispatch in terms of quantity and type.

With this letter, I confirm the reliability and timeliness of the services provided by CRI. Additionally, the company demonstrates great flexibility, commitment, and a responsible approach to cooperation, which makes it a highly recommendable partner.

Between 04.2023 and 05.2024, CRI provided a service for Volkswagen Motor Polska Sp. z o.o. involving the preparation of crankshafts for shipment to the AHM Gyor plant. The service included repackaging crankshafts of a given type into appropriate packaging within the specified timeframe and in accordance with the logistics and quality guidelines of VWMP.

Simultaneously, CRI also carried out packing and unpacking of engine blocks for the purposes of VWMP logistics banking, using stationary hoisting equipment.

With these references, I confirm the timeliness of the services provided by CRI. Their flexibility, full availability, and effective communication are especially noteworthy. Based on this, I recommend CRI as a competent and trustworthy partner.

Since 2019, CRI has been providing FM Logistic with in-plant logistics services, which include a range of warehouse operations using both low-lift and high-lift trucks.

The service standards meet our expectations. Excellent communication allows for quick consideration of our additional requirements. A particularly important aspect of our cooperation with CRI is its nationwide reach, which enables us to use CRI’s services across several FM Logistic platforms in Poland, including Olszowa, Jarosty, Odrzywołek, and Mszczonów.

CRI is a trustworthy company that I confidently recommend as a professional service provider.